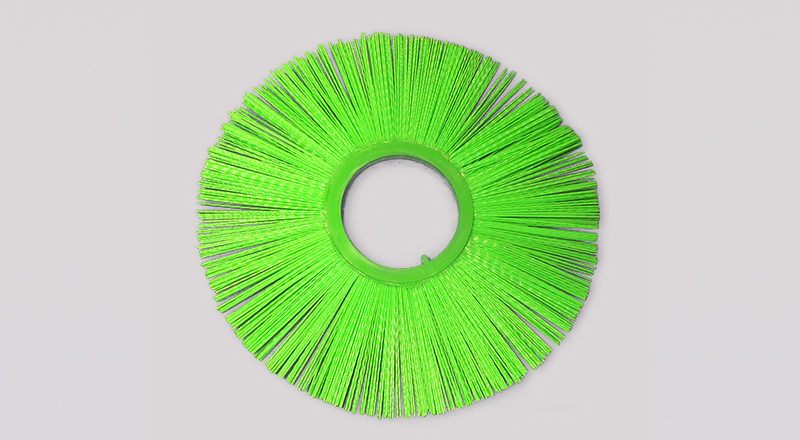

Brush rings flat

With the brush rings flat, the synthetic core and filling material are pressed to a brush ring. Through this process, the ring is made from one piece and no steel is used. As a result, this brush ring has less chance of fibre breakage and there is no risk of corrosion. The brush rings flat can be used as an alternative of the brush ring with steel profile. Both rings have a width of 15 mm. However, this pressed ring does not use spacer rings due to its construction.

The brush rings flat can be easily mounted to a roller brush or sweeping roller. This is done by putting the brush rings on to a machine core. The roller brush can then be used for removing leaves, dirt and other objects, such as rubber from tires, from large surfaces, car parks and runways.

Advantages of brush rings flat:

- Optimal sweeping function.

- Less chance of fibres breaking.

- No rust formation.

- 20 to 40% more filling material.

- Various brush diameters available (important for the sweeping pattern).

- Compared to brush rings with steel profile, spacer rings are not needed.

- The core of your machine will always be completely filled no matter the length.

- Most common diameters and dimensions available from stock.

Configurations

| Bore diameter in mm | Standard brush diameter in mm |

|---|---|

| 128 | 380 - 400 - 500 - 550 |

| 178 | 500 - 600 |

| 254 | 700 - 750 - 800 - 915 |

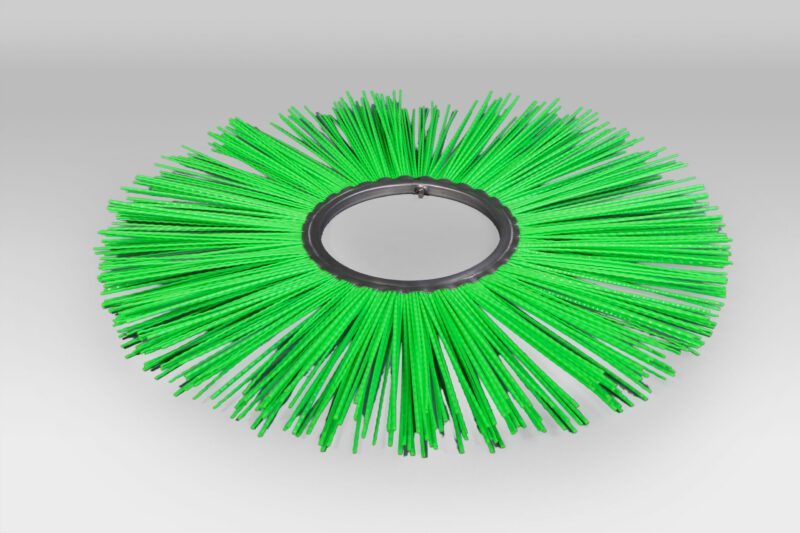

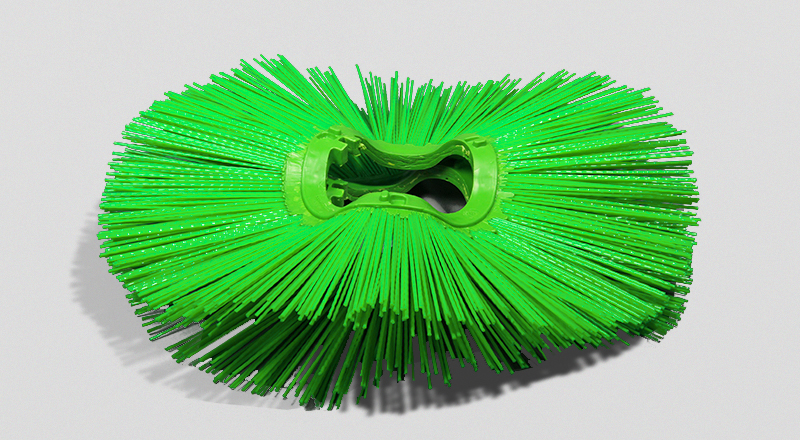

Brush rings Wave Ring

KOTI has a special type of brush ring: The Wave Ring. This brush ring is made out of synthetic materials and has a unique shape. Thanks to this shape the rings can be easily assembled in to a roller brush. The roller brush can then be used for removing leaves, dirt and other objects, such as rubber from tires, from large surfaces, car parks and runways.

Advantages of brush rings Wave Ring:

- Optimal sweeping function.

- Less chance of fibres breaking.

- No rust formation.

- 20 to 40% more filling material.

- No spacer rings are needed.

- Due to the Wave form, dirt is better removed.

- Longer working time.

- Most common diameters and dimensions available from stock.

Configurations

| Bore diameter in mm | Standard brush diameter in mm |

|---|---|

| 128 | 350 - 380 - 400 - 500 - 550 |

| 178 | 500 - 600 - 650 - 700 |

| 254 | 700 - 750 - 800 - 915 |

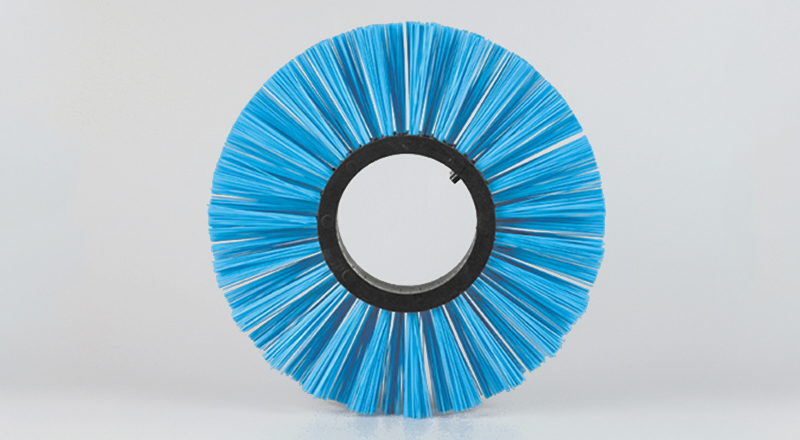

Brush rings tufted

For this brush ring holes are drilled in the core of the brush, using computer-controlled machines. After this process bundles of filling material are tufted into the holes and fixed with a steel staple. The brush rings tufted are used to make a roller brush or sweeping roller. This is done by putting the brush rings on to a machine core. The roller brush can then be used for removing leaves, snow and other objects, such as rubber from tires, from large surfaces, car parks and runways.

Advantages of brush rings tufted:

- Optimal flexibility in the brush filling.

- Various brush diameters available (important for the sweeping pattern).

- The core of your machine will always be completely filled no matter the length.

- Compared to brush rings with steel profile, spacer rings are not needed.

- Most common diameters and dimensions available from stock.

Configurations

| Bore diameter in mm | Standard brush diameter in mm | Machine type |

|---|---|---|

| 76 | 300 - 360 - 700 | Beam & custom |

| 110 | 300 - 350 - 400 | Johnston & custom |

| 128 | 380 - 400 - 450 - 500 | Beam, Johnston & custom |

| 178 | 500 - 600 - 700 - 900 | custom |

* Please contact us for more information about custom Machine types.

Contact us